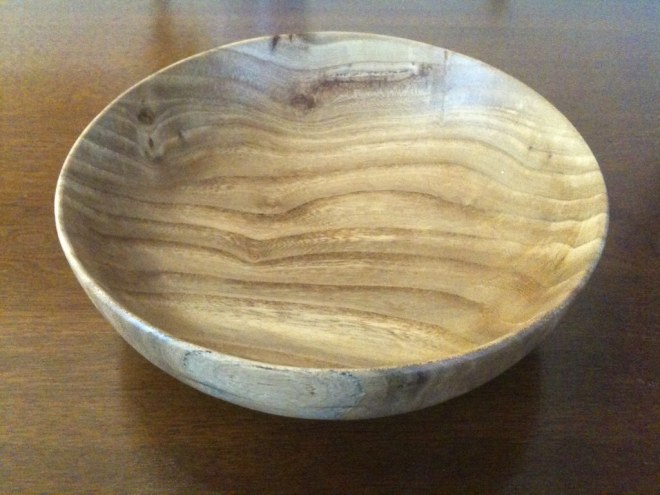

8 15/16″ x 3 3/8″ from a log of about 12″ diameter. A blank, with a wall thickness just under an inch was turned in October. After monitoring the weight change in the blank (and knowing I wanted a bowl to bring to France), I chose to complete the turning. As it happens, the wood was still a little yet yielding a slightly distorted round as I completed the final turning. The pear wood log was from Paul Simmons of Valley Trees. Sanding was done up to 4000 grit. The finish is “salad bowl” finish with three coats of wax. Some lines are still present but are possibly within wax coat.

Update: This bowl was given to my friend and sometimes colleague Eric Duplan of TESIS. He lives with his family at an old farm in the Tourraine, providing space for his sizable metal and woodworking atelier and baking operations. This bowl receives heavy use and has survived a number of excursions in a microwave.